EPC-School 2012

M for Mechanical

M for Mechanical

Topic - PUMPS, SEALS

1. What is the operating principle of rotodynamic vs

positive displacement pump?

2. What is ‘head’ of a pump?

4. What are the application criteria with respect to

pressure and flow for centrifugal and positive displacement pumps?

5. What are the different types of radial and axial thrust bearings?

6. What are the different types of positive displacement

pumps?

7. What are the different constructions of centrifugal

pumps?

8. What is the advantage of a double volute casing over

single volute?

9. What are the specific requirements needed for a

centrifugal pump used in slurry application?

10. What is cavitation?

11. What are the causes of cavitation?

12. How is axial thrust generated in pump?

13. Why is hydrotest of equipment done?

14. Which API governs centrifugal pumps?

15. What does NPSH mean?

16. How NPSH affects the pump performance?

17. What are NPSHa and NPSHr?

18. What are the affinity laws?

19. What are the different impeller types and their applications?

20. What types of pumps are used for metering application?

21. What are the effects of cavitation?

22. What are normal and rated operating point for a given

pump?

23. What is system resistance? How does system resistance

affect pump operating point?

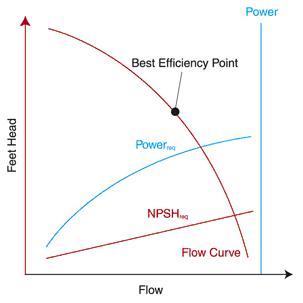

24. Draw a typical performance curve (head Vs Flow) for a

centrifugal pump.

25. Which consumes more energy at same volume flow rate and

differential pressure: lighter or

heavier liquid?

26. What are the different types of sealing mechanism in a

pump? State typical application for each.

27. What are primary and secondary sealing elements in a

mechanical seal?

28. What are the application criteria for single / double (including

tandem) mechanical seals?

29. Which seals are recommended in case of toxic service?

30. List some of the flushing plans

31. What is the function of pumping ring in seal flushing

plans and in which plans it is used?

32. Which buffer/barrier fluid is generally used in seal

flushing plans?

33. Which flushing plan is for inboard seal in high

temperature services?

34. How can we detect failure of flushing plan 23?

35. In flushing plan 53, seal pot pressure alarm is

generated when pressure is increasing or decreasing?

Answers to Above Questions-

1. In positive displacement pumps energy is periodically

added to closed fixed volume fluid resulting in increase in pressure. In

rotodynamic pumps energy is continuously imparted to the liquid with the help

of rotating element.

2. Head of the pump is the energy imparted to the fluid by

the pump equivalent to a height static column of the liquid being pumped

3. Wear rings are used on impellers and on casing on the

suction eye to avoid the recirculation of liquid being pumped and to protect

the impeller or casing from damage due to contact.

4. Centrifugal pumps are used mostly where variable flow and

near uniform discharge pressure is required and reciprocating pumps are used

when constant flow and variable discharge pressure is required. Centrifugal

pumps are used for high flow and low pressure applications while reciprocating

pumps are used for high pressure and low flow applications.

5. Journal bearings & antifriction bearings

6. Positive displacement pumps are classified into rotary

and reciprocating types.

Reciproacating pumps are again classified on the basis of

use of piston ,plunger or diaphragm for compression.

Rotary type is classified as screw type, progressive cavity

type, gear type, vane type, lobe type.

7. Overhung type, Between bearing type, vertically suspended

type

8. Double volute casing design increases the operating range

of pump without much change in radial vibration. In double volute casing the

radial load on the impeller gets balanced whereas in single volute casing radial

load on impeller are balanced for a small range of flow.

9. High wear ring clearances, special materials of

construction, Back vanes to prevent slurry from entering seals

10. The phenomena of vapours entering the pump, formation of

bubbles and subsequent collapse of the bubbles at higher pressure regions is

called cavitation.

11. Cavitation occurs when vapour pressure of pumping liquid

goes higher than pressure of liquid or when vapour enters the pump through

suction line.

12. Impeller (hence pump) is subjected to axial thrust

because a portion of the front wall is exposed to suction pressure (eye)

whereas the whole of its back wall is exposed to discharge pressure.

13. To check the integrity of the casing of pump & to

check for leaks or defects.

14. API 610.

15. Net Positive Suction Head is the difference between

total head and the vapour pressure head at the suction of a pump

16. Low NPSH may result in cavitation. NPSH is needed to

keep the centrifugal pump filled with liquid and in order to avoid vapour

formation in the impeller.

17. NPSHa is the net positive suction head available to the

pump, and NPSHr is the net positive suction head required by the pump to avoid

problems such as cavitation. NPSHa must be greater than the NPSHr for a pump to

run properly.

18. For two geometrically similar pumps following equations

can be derived which are called affinity laws:

Q ∞ N Q

∞ D3

H ∞ N2

H ∞ D2

P ∞ N3 P

∞ D5

where Q is flow, H is head, P is power, N is speed, D is

diameter

19. Different types of impellers are

Closed impellers : shrouds or sidewalls enclosing vanes

Open impellers : no shrouds or walls to enclose vanes

Partially open : shroud only on one side of vanes

20. Plunger type, lobe type reciprocating, diaphragm type

pumps

21. The effects of cavitation are drop in flow rate, damage

to impellers, high noise, high vibration.

22. Normal operating point on the pump curve at which the

flow the pump is currently operating at and rated point is the point at which

the pump is guaranteed to operate at

23. System resistance is the resistance offered to the flow

of the liquid by the system

If the system resistance increases then the flow rate

decreases and the pump operating point shifts and vice versa.

24.

25. Heavier fluid

26. Sealing in a centrifugal pump can be done either with

gland packing or with mechanical seals.

Gland packings are

generally used for a clean and cheap services such as quench water, fire water

etc.

Mechanical seals are

used where liquid is flammable. Sour oil pumps, VGO, column bottoms etc

27. The primary sealing elements are the flat faces of

rotary component and stationary component.

The secondary sealing

elements are elastomeric o rings, PTFE wedge, gaskets.

28. Double mechanical seals are used where leakages to

atmosphere are not tolerated such as toxic fluids and fluid which autoignite at

atmospheric conditions or when environmental pollution is an issue.

Single seals are used for purposes where minor leakages to

atmosphere can be tolerated.

29. In case of toxic services double mechanical seals are

preferred with flushing plan 53.

30. The major seal flushing plans are

11, 21, 23, 32,

52, 53, 62 etc

31. The function of pumping ring is to pump back the liquid

from seal chamber to seal pot or reservoir. Pumping ring is used in plans 23,

52, 53

32. Therminol 66, Molykote L1605, diesel.

33. plans 21, 23

34. By observing cooler inlet and outlet temperatures.

35. Decreasing.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.